Simplifying? Net Zero Modular Buildings

For those in the built environment, particularly those of us who specialise in sustainable design, this increased level of concern is long overdue. It’s no secret that the industry (construction) is responsible for a huge proportion of emissions; 40% to be exact, and the move toward a zero-carbon future has been sluggish and fraught with perceived difficulty.

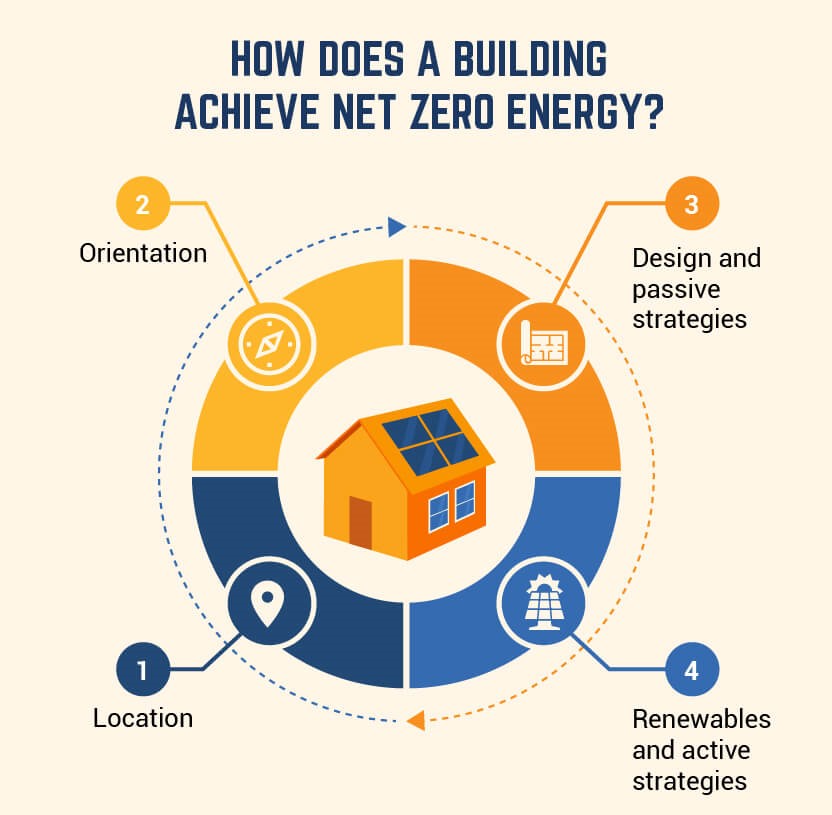

The good news is that the decarbonisation of buildings is possible. We’ve seen more action around net zero in the past 12 months than in the entire preceding decade, and the industry’s approach is becoming clear – particularly for new buildings. We have simplified the approach to net-zero carbon buildings into the following steps.

Location

To construct a net-zero energy building, you must consider several conditions. The building site, where you are building, the climate and the building’s exposure all have an effect. Among other things, take into account: Climate, Sun, Wind patterns, Temperature, and Rain patterns.

Passive design optimisation

Utilise the useful daylight to ensure the best possible daylight for occupants, whilst limiting artificial lighting use, reducing glazing areas, glare, heat loss, cooling loads and improving views and occupancy comfort. This enables full or partial natural ventilation for a proportion of the year, supplemented by mechanical systems to provide heat recovery in winter and cooling in summer where required.

Orientation

The orientation of the building depends on the success of achieving net-zero energy. Certain renewable energy generation mechanisms, like solar panels, work best when the building is facing south. But factors that conserve energy are also important. Besides harnessing the sun’s energy, you can conserve by orienting your building to take maximum advantage of the shade. In warm climates, this means you’ll need to use the air conditioning less to keep your building cool.

Reduce operational energy demand and consumption

Prioritise fabric measures to drive down heating, cooling and lighting demand. Widen temperature set bands and allow occupants to adapt and control their comfort by adjusting clothing, using fans and natural airflow. Review drivers of energy consumption to determine suitable alternate approaches that can be taken.

Challenge conventional design practices and standards, recognise that the same solutions will result in the same energy-intensive buildings and look for alternative solutions. Utilise industry standards approaches like NABERS, Passivhaus and embed energy savings at every stage and meet best practice energy intensity targets.

Eliminate fossil fuels

Prioritise fifth-generation heat networks and electric heat pump technologies over fossil fuel technologies to supply affordable low carbon energy. When considered in conjunction with zero-emission vehicles, this will significantly improve local air quality.

Renewables

Provide onsite renewable energy and storage where possible If the building is industrial scale, wind generators might be used on-site rather than off-site. Solar panels might be the way to go for new homes or even ones that can be converted. Active strategies reduce energy consumption during the building process through the use of renewable energy strategies, such as:

Photovoltaics

Photovoltaics is the direct conversion of light into electric power using semiconducting materials such as silicon. Each solar panel contains numerous photovoltaic cells, which work together to produce electricity.

Wind power

The wind is a kind of solar energy produced by three factors. It’s affected by the sun unevenly heating the atmosphere, irregularities in the Earth’s surface, and the planet’s rotation. The resulting wind turns propeller blades around a rotor, which spins a generator, creating electricity.

Hydroelectric power

Hydroelectric plants capture the energy of falling water and convert it into electricity. Water flows downhill and is captured by a reservoir behind a dam. This reservoir acts like a battery, releasing water during periods of peak demand to produce power.

Biomass

Biomass stores chemical energy from the sun, produced by plants through photosynthesis. It can be burned directly to produce heat or can be converted into renewable liquid and gas fuels. Biomass can be as simple as a log on a fire. It’s like a solar battery, which releases bioenergy.

Geothermal power

Geothermal power involves water pressure in the form of steam. Geothermal wells drilled a mile or two underground pump hot water to the surface. There, the pressure drops and the water turns into steam. The steam spins a turbine connected to a generator, producing electricity.

Solar power

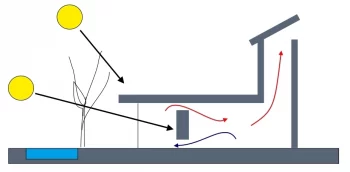

Sunlight shining on a panel is absorbed by photovoltaic cells in the panel. This creates an electrical charge in response to an electrical field in the cell, producing electricity.

Solar thermal

Solar thermal power systems use mirrors to collect sunlight and concentrate it. This raises the temperature until it is high enough to produce electricity. Examples include curved parabolic troughs, such as those used in the Mojave Desert.

Net-zero energy buildings react in various ways to their local electricity grid. Whether the grid is integrated or conventional affects the way it interacts with buildings and strategies (such as renewable energy sources). Energy moves between the grid and conventional energy buildings in a single direction. It flows from the grid to the building, utilizing conventional metering. Moderately responsive buildings have interactive demand responses.

Buildings that are fully integrated with the grid include passive efficiency features as well as renewable energy production on site. Put another way, the two types of ZNE building typologies must work together to optimize grid performance: Renewable-oriented (active strategies) / Efficiency-oriented (passive strategies). Utilizing both passive and active strategies will prove most beneficial to the relationship between the utility grid and ZNE buildings.

Limit upfront embodied carbon

Consider all upfront carbon associated with the initial build and restrict carbon intensity to a maximum of 500kgCO2/m2. This applies to all construction materials from extraction to installation, including the emissions associated with the construction works themselves. Use modular construction approaches, design for deconstruction using circular economy principles, and limit waste generated during construction.

Whole Life Carbon

Consider whole life carbon in conjunction with whole life costing. Measure all upfront and operational carbon emissions, including maintenance, fit-outs, minor and major refurbishments, deconstruction and the reuse of building materials. All this must be considered over an extended design life allowing for durability and robustness.

Visited 555 Times, 2 Visits today